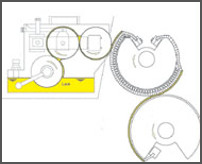

Inline Coating Unit

LACO SP 52 for Heidelberg PM/SM 52

Properties of the LACO Inline Coating Unit

- Increased Productivity of your Heidelberg 52 press with attached coating unit through printig and coating in one sheet

passage on the last press tower.

- Refinement of the printed sheets by increased gloss and contrast.

- Increased protection of printed sheets against mechanical influences. If UV-coatings are used, even a protection

against influences is present.

- A wide range of usage and application possibilities.

- Water based protective coatings are fast dry on the surface. The result of this is:

1. time saving by an earlier possible perfecting/processing of printed and coated sheets

2. effectively reduction of spray powder possible

3. safe production through reduced blocking, sticking and gluing tendencies

4. double sided production possible after short waiting time

5. no additional time required to eliminate pile problems like mentioned above

- Effect coating applications possible like Drip-Off method (special overprint varnish + high gloss water

based coating) or Hybrid method (special overprint varnish + UV-coating)

- A LACO coating unit can be combined with an LACO IR-dryer. The use of such an integrated LACO IR/Hot-Air

Combination dryer enables:

1. Gloss and High-Gloss water based coating applications inline (wet-on-wet)

2. often a further spray powder reduction possible

3. a further increase of production safety and productivity

passage on the last press tower.

- Refinement of the printed sheets by increased gloss and contrast.

- Increased protection of printed sheets against mechanical influences. If UV-coatings are used, even a protection

against influences is present.

- A wide range of usage and application possibilities.

- Water based protective coatings are fast dry on the surface. The result of this is:

1. time saving by an earlier possible perfecting/processing of printed and coated sheets

2. effectively reduction of spray powder possible

3. safe production through reduced blocking, sticking and gluing tendencies

4. double sided production possible after short waiting time

5. no additional time required to eliminate pile problems like mentioned above

- Effect coating applications possible like Drip-Off method (special overprint varnish + high gloss water

based coating) or Hybrid method (special overprint varnish + UV-coating)

- A LACO coating unit can be combined with an LACO IR-dryer. The use of such an integrated LACO IR/Hot-Air

Combination dryer enables:

1. Gloss and High-Gloss water based coating applications inline (wet-on-wet)

2. often a further spray powder reduction possible

3. a further increase of production safety and productivity

- Pre-Conditions to attach a LACO 52 coating unit to a Heidelberg 52 press with low pile delivery:

1. A Plus Version (numbering and imprinting unit/preparation) must be already installed in all

Heidelberg presses which get upgraded with LACO coating unit.

2. An Interface STA Adaptor must be installed in all Heidelberg Printmaster PM 52 and Speedmaster

SM 52 presses.

Technical Specifications and Parameters

1. A Plus Version (numbering and imprinting unit/preparation) must be already installed in all

Heidelberg presses which get upgraded with LACO coating unit.

2. An Interface STA Adaptor must be installed in all Heidelberg Printmaster PM 52 and Speedmaster

SM 52 presses.

Technical Specifications and Parameters

| - Maximum coating application format: | 500 x 350 mm |

| - Gripper Edges: | ca. 12 mm |

| - Maximum coating production speeds: | 10.000 sheets/h |

| - Suitable Coatings: | Water based (Aqueous) Coating Water based Blister Pack Coatings UV-Coatings |

| - Viscosity of Coatings: | 30-40 Sek. DIN Cup 4 |

Contact |